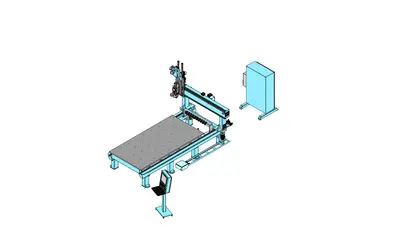

The Bryce3 emerges as a price and performance-leading 3-axis CNC machine, aligning the core strengths of the Bryce and Pinnacles series. This machine is engineered for versatility, offering precision machining across a broad spectrum of materials. With enhanced performance features, the Bryce3 is designed to meet the diverse needs of modern manufacturing, providing reliability, ease of use, and efficiency. It’s the go-to solution for businesses seeking to elevate their production capabilities with a machine that offers both high quality and adaptability.

• Enhanced Versatility: Suitable for a wide range of materials.

• Precision Machining: High accuracy in 3-axis operations.

• Focused Strengths: best in class for essential 3 axis machining/routing.

• Reliability and Efficiency: Optimized for consistent performance.

• Ease of Use: User-friendly interface for streamlined operation.

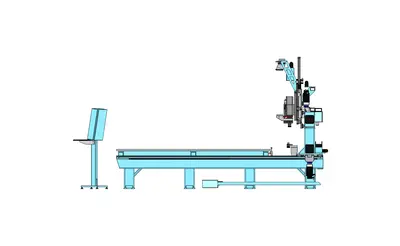

Min – Max Axes Strokes * DMS standard configuration: X axis = Bridge axis

X: 5’/6′

Y: 5’/12′

Z: 305 (12″)/406 (16″)

C: C-Axis optional

Operating Units and Spindles

Max Power (S1 / S6): 13kW/ 15kW

Max rpm: 24000

Spindles Range (min-max kW)(S1): 4.5-13kW

Units Range: Hiteco MT200, MT201, PT300, PT400

Specifications

Transmission type: Rack & Pinion

Feedback encoders: N/A

Motor Encoders: All Absolute

Machine Envelope (Table Size): 5’x(5′, 10′, 12′, 15′, 20′, 25′)

6’x(10′, 12′)

HMI + NCs: Fagor 8065

Dynamic Performances

Avg Speed (average 3 axis) inch/min: NA

Avg Acceleration inch/min2: NA

Max Accuracy: .0025″-.005″

Toolchanger Standard Option(s)

type: Rack-Carousel-Manual

max tot: 10

We use cookies to improve your experience. Privacy Policy.