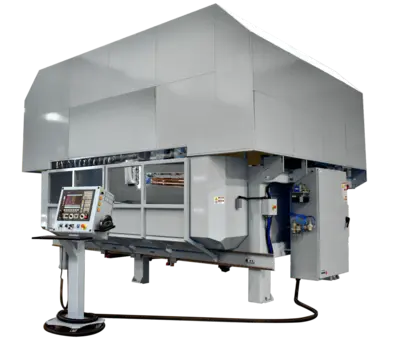

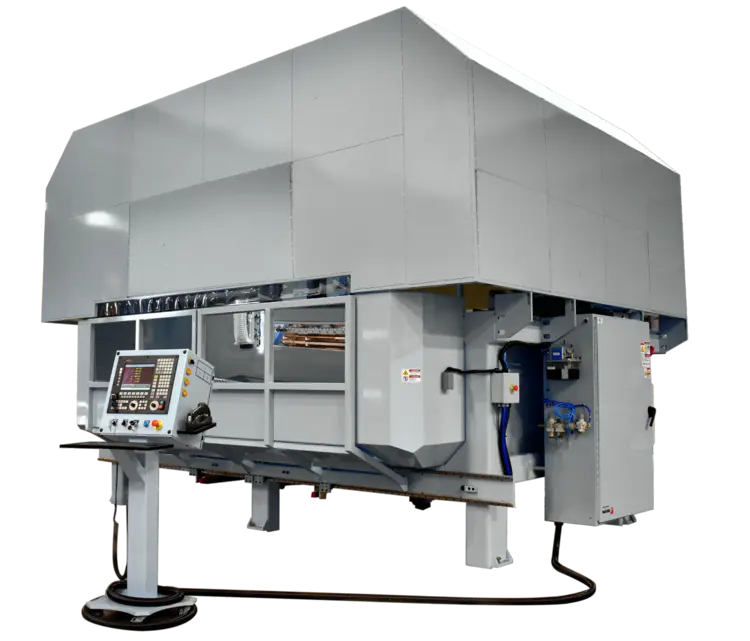

Introducing Glacier3, a remarkable evolution in the Glacier series now with 3-axis precision. This fully enclosed machine leverages the robust foundation of the Glacier’s advanced technology, tailored for exceptional accuracy and versatility in a simpler 3-axis format. Glacier3 is engineered to streamline operations across diverse materials, ensuring reliability and precision for every project. Offering customization to fit your specific needs, backed by unparalleled support, the Glacier3 is your partner in elevating manufacturing efficiency.

• 3-Axis Precision: Focused accuracy for streamlined operations.

• Versatility in Materials: Capable of processing a wide range of materials with ease.

• Reliability: Engineered for consistent performance in demanding environments.

• Customization Options: Adaptability to meet specific production requirements.

• Dedicated Support: Robust after-sales service and warranty coverage.

Min – Max Axes Strokes * DMS standard configuration: X axis = Bridge axis

X: 4’/12′

Y: 3’/6′

Z: 750 (30″)

C: C-Axis optional

Operating Units and Spindles

Max Power (S1 / S6): 18kW / 21kW

Max rpm: 24000

Spindles Range (min-max kW)(S1): 8-18kW

Units Range: Hiteco MT200, MT201, PT300, PT400, PT500

Specifications

Transmission type: Spinning Ball Nut & Recirculating Ball Screw

Feedback encoders: Scales available as option

Motor Encoders: All Absolute

Machine Envelope (Table Size): 4’x3′, 5’x’5′, 10’x5′, 12’x(3′ or 6′)

HMI + NCs: Fagor 8065

Dynamic Performances

Avg Speed (average 3 axis) inch/min: 35560 (1400″)/min

Avg Acceleration inch/min2: NA

Max Accuracy: .0025″-.005″

Toolchanger Standard Option(s)

type: Rack-Manual

max tot: 10/12

We use cookies to improve your experience. Privacy Policy.