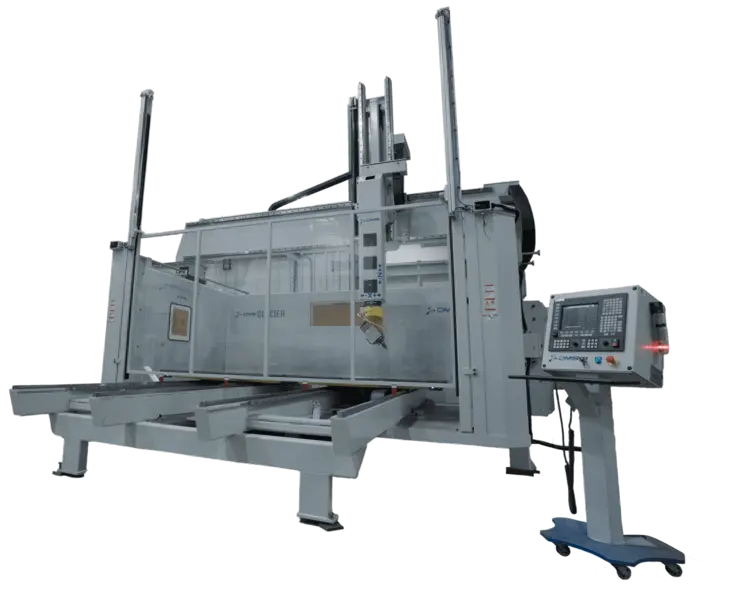

Explore the pinnacle of manufacturing innovation with the Glacier5, our advanced 5-axis CNC machine. Designed with a fully enclosed architecture for those who demand precision and versatility, Glacier5 revolutionizes the way you work with a wide array of materials and material presentation options. From intricate aerospace components to complex automotive parts, this machine offers unmatched accuracy, speed, and adaptability. Tailored solutions and expert support ensure that your manufacturing needs are met with the highest standards. Elevate your production capabilities and achieve excellence with Glacier5.

• Enhanced Precision: Superior accuracy for complex geometries.

• Material Versatility: Capable of processing a diverse range of materials.

• Advanced Technology: State-of-the-art 5-axis functionality.

• Customization Options: Tailored to meet specific manufacturing needs.

• Dedicated Support: Comprehensive after-sales support and warranty.

Min – Max Axes Strokes * DMS standard configuration: X axis = Bridge axis

X: 5’/12′

Y: 5’/10′

Z: 1830 (72″)

B: ‘(+/-) 115° / 130°

C: DMS: (+/-) 363° (opt. Continuous) Hiteco: (+/-) 320°

Operating Units and Spindles

Max Power: 20kW

Max rpm: 24,000

Spindles Range (min-max kW): 8-20kW

Units Range: Tilt K Plus, Tilt H Plus, Tilt V, Tilt W, DMS Standard Yoke, DMS Cast Yokes

Specifications

Transmission type: Spinning Ball Nut & Recirculating Ball Screw on Bridges up to 14′(4267mm), Gantry always Rack & Pinion

Feedback encoders: Scales available as option

Motor Encoders: All Absolute *Exception = Rotaries are incremental w/ Continuous C option

Machine Envelope (Table Size): Bridge Length: 5′, 6′, 7′, 8′, 10′, 12′ Depth: 4′, 5′, 6′

HMI + NCs: Fagor+ Fagor

Dynamic Performances

Avg Speed (average 3 axis) inch/min: 1333

Avg Acceleration inch/min2: 70

Max Accuracy: .002″-.005″

Toolchanger Standard Option(s)

type: Rack-Carousel-Man

max tot: 10/12

We use cookies to improve your experience. Privacy Policy.