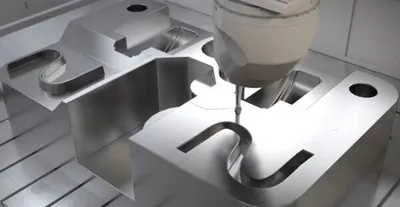

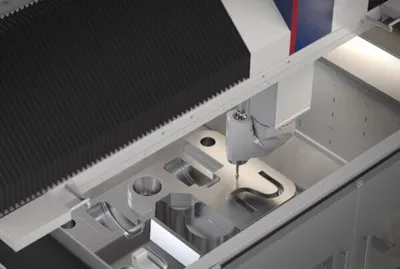

The CMS vm 30 CNC machining center is the ideal solution for milling complex three-dimensional parts in steel, aluminum, light alloys and composite materials that require precision, repeatability and excellent finishing, with reduced cycle times. vm 30 was devise and designed to satisfy the needs of the aeronautical, automotive, mold and design industries, guaranteeing roughing, semi-finished and finished processing of medium-large components.

• All the structural components have been designed on the basis of careful analysis (structural, static, dynamic and thermal) thanks to the highest performing systems on the market. The aim is to achieve the best performance in terms of speed and precision while keeping cycle times down.

• High configuration based on one’s own production needs thanks to an extensive range of machining units and electro-spindles

• Maximum dynamics thanks to the high acceleration, high speed and top-class rigidity

• Built-in careening that cordons off the work area to provide the operator with maximum safety

• Energy saving: led lights and automatic on/off system on the machine and motors

vm 30 is available in the monobloc version (vm 30 K) and open frame (vm 30), the latter with strokes up to 6 meters (higher than requested).

Advantages:

NEW! New TILT M head with 3 torque motors with a braking torque of 4000 Nm and a wide range of electrospindles with rated powers up to 47 kW at 15,000 rpm HSK A 100 and 24,000 rpm HSK A 63. The new head, coupled with a 70 bar pump for internal cutting fluid flow, can perform deep drilling and significant material removal, giving the customer an operating unit for every need.

SUSTAINABLE INTEGRATION: Monobloc machine with integrated table, 10000 kg/m2 load capacity, supported by dedicated levelling devices. There is no need for heavy-duty foundations, resulting in shorter installation and commissioning times.

TOP OF THE RANGE FINISHING: Very strong structures and 4 guides on the longitudinal axis provide high geometric precision to ensure perfect machining in terms of accuracy and repeatability. The dynamic, fluid kinematic chain can achieve excellent finishing quality with improved low-backlash power reducers.

AXES STROKES

X: ........... 2200-4000-6000 mm

Y: ........... 3000 mm

Z: ........... 1300 mm

MACHINE WEIGHT 32,000 KG

MACHINING UNITS AND ELECTRO-SPINDLES:

MACHINING UNIT TORQUE 5

AXES ROTATION [°] C / A: ± 300 / ± 110

TORQUE S1/S6 [Nm] C / A : 783 - 1300 / 521 - 868

BLOCKING TORQUE [Nm] C / A: 1000 / 1000

AXES ROTATION PRECISION [arcsec] C - A: ± 6

ELECTRO-SPINDLES

- Power [kW]: 32, 31

- Torque [Nm]: 68, 100

- Speed [revs./ min.]: 24000, 15000

- Pivot Point: 228, 228

- Attachment: HSK 63A, HSK 63A

MACHINING UNIT TILT G

AXES ROTATION [°] C / A: ± 360 / ± 120

TORQUE S1/S6 [Nm] C / A : 787- 1560 / 504 - 998

BLOCKING TORQUE [Nm] C / A: 3000 / 3000

AXES ROTATION PRECISION [arcsec] C - A: ± 2.5

ELECTRO-SPINDLES

- Power [kW]: 42, 42, 30

- Torque [Nm]: 34, 67, 95

- Speed [revs./ min.]: 24000, 24000, 22000

- Pivot Point: 250, 250, 250

- Attachment: HSK 63A, HSK 63A, HSK 63A

MACHINING UNIT TILT M

AXES ROTATION [°] C / A: ± 360 / ± 120

TORQUE S1/S6 [Nm] C / A : 787 - 1560 / 830 - 1472

BLOCKING TORQUE [Nm] C / A: 4000 / 4000

AXES ROTATION PRECISION [arcsec] C - A: ± 2

ELECTRO-SPINDLES

- Power [kW]: 42, 42, 30, 47, 73

- Torque [Nm]: 34, 67, 95, 150, 70

- Speed [revs./ min.]: 24000, 24000, 22000, 15000, 28000

- Pivot Point: 345, 345, 345, 345, 345

- Attachment: HSK 63A, HSK 63A, HSK 63A, HSK 100A, HSK 63A

We use cookies to improve your experience. Privacy Policy.