3 and 5 axis machining centres with mobile gantry structure dedicated to the machining of plastic materials and advanced materials and characterized by a rigid and stable frame.

• spindles up to 15 kw and 24.000 rpm ensure high removal capacity and top finishing and accuracy levels under any conditions

• the aluminium worktable is characterized by perfect planarity, ensuring clamping accuracy and advanced nesting machining even with the most severe machining operations on technical details

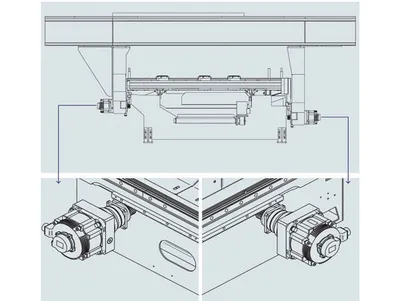

• gantry structure driven by a highly dynamic dual motor. Solution dedicated to the processing of plastic materials and advanced materials

Advantages:

HIGH REMOVAL AND PERFECT FINISHING

Removing capacity increased by 7%, faster roughing cycles and absolute compliance with the strictest finishing tolerances.

The fixed table and mobile gantry architecture with dual motorization, consisting of a rigid frame equipped with high-precision front and rear sliding guides, ensures maximum efficiency during heavy removal and incomparable finishing quality in the whole work area.

FLEXIBILITY AND CLAMPING EFFECTIVENESS

The built-in direct vacuum system and the T-slots allow the optimal clamping of the sheets and the positioning of all types of mechanical clamping equipment. Tolerances are always under control owing to a multi-functional and highly efficient aluminium work table that ensures perfect planarity over time.

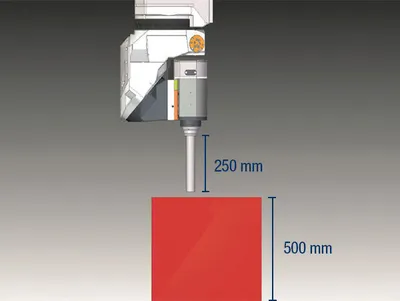

LIMITLESS MACHINING

The high workpiece throughput dimension and the Z axis travel allow machining workpieces up to 500 mm high. Ideal solution in the production of engineering and prototype parts in plastic materials.

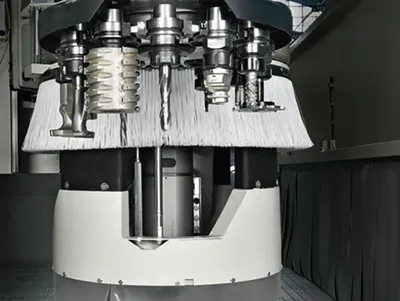

THE POWER OF 5 AXIS

PRISMA operating units with 5 interpolating axes equipped with power up to 17Kw 24000 rpm, specifically configured for the processing of plastic materials: this is ideal solution for the production of technical components made of the most performing and demanding resins.

AXES

X-Y-Z axes max. speed (PRO SPEED version) m/min: .... 95-90-30

X-Y-Z axes max. speed (PRO SPACE version) m/min: .... 25-90-30

Z axis work-piece passage (max.) mm: ................ 500

MACHINING HEAD

Axes electrospindle motor power (max) kW: ........... 17

3/4 axes electrospindle motor power kW: ............ -

5 axes electrospindle 5 rotation speed (max.) rpm: .. 24000

3/4 axes electrospindle rotation speed (max.) rpm: .. -

DRILLING UNIT

Vertical and horizontal spindles (max.) n.: ......... 26

Rotation speed rpm: ................................. 8000

TOOL CHANGERS

Tool store on machining head posizioni: ............. 12

Rear tool store posizioni: .......................... 48

Side tool store posizioni: .......................... -

Front tool store posizioni: ......................... 16

INSTALLATION

Exhaust air consumption m³/h: ...................... 4430

Compressed air consumption (min.-max.) Nl/min: ..... 350-550

We use cookies to improve your experience. Privacy Policy.